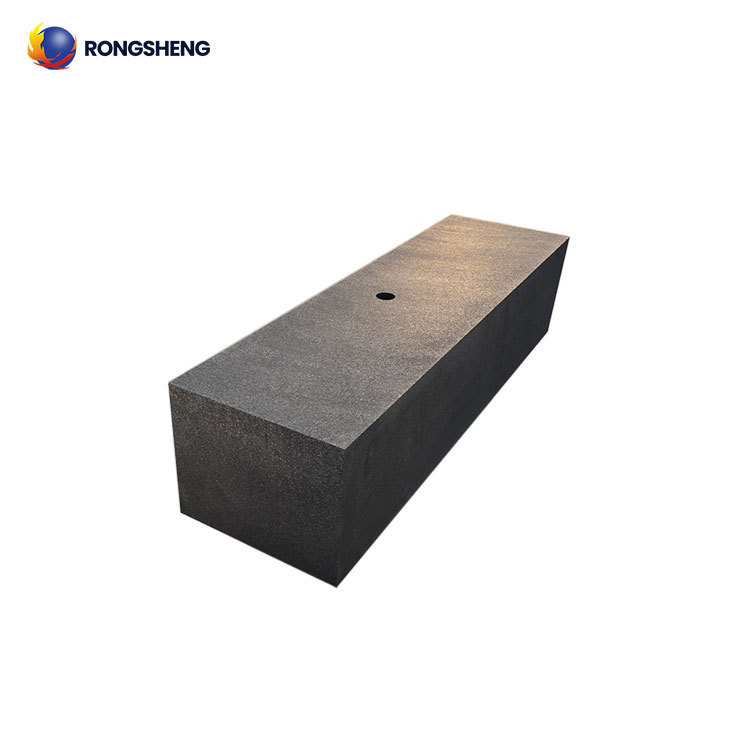

Blast Furnace Microporous Carbon Bricks

- Thermal conductivity.

- Alkali resistance.

- Iron molten corrosion resistance.

- Oxidation resistance.

- Iron molten permeability resistance.

We are Here to Help!

Email: sales@hy-refractory.com

WhatsApp: +86 185 3831 2977

Rongsheng blast furnace microporous carbon bricks not only have excellent conventional properties but also have excellent performance in use, including alkali resistance, thermal conductivity, iron molten corrosion resistance, oxidation resistance, and iron molten permeability resistance. At the same time, the air permeability is low, the average pore size is less than 1 μm and the pore volume percentage of pore size less than 1 μm is greater than 70%. Microporous carbon bricks for blast furnaces are mainly used in the hearth and bottom of blast furnaces. They are resistant to alkali corrosion and iron molten penetration. They can achieve the purpose of high efficiency, energy saving, and long life of iron-making blast furnaces.

Raw Material Composition of Microporous Carbon Bricks

Microporous carbon bricks are made of high-temperature (1500 ~ 2000℃) electric calcined anthracite as the main raw material, with appropriate amounts of natural graphite, aluminum oxide, pure silicon powder, silicon carbide and other materials added, and the binder is medium-temperature asphalt. Adding pure silicon or silicon carbide can effectively reduce the pore size, reduce the penetration of molten iron and slag, and improve the thermal conductivity and oxidation resistance of carbon blocks. Adding aluminum oxide can increase the carbon block’s resistance to alkali metal salt corrosion and molten iron corrosion. The production process of microporous carbon bricks is the same as that of ordinary carbon bricks.

Physical and Chemical Indicators of Microporous Carbon Bricks for Blast Furnaces in Rongsheng

Physicochemical performance indicators of microporous carbon bricks for blast furnaces manufactured by Rongsheng.

| Physical and Chemical Indicators of Blast Furnace Microporous Carbon Bricks in Rongsheng | ||

| Bulk Density g/cm3 | ≥1.58 | |

| Apparent Porosity % | ≤16 | |

| Compressive Strength MPa | ≥38 | |

| Flexural Strength MPa | ≥9 | |

| Average Pore Size μm | ≤0.5 | |

| <1μm Pore Volume Ratio % | ≥75 | |

| Thermal Conductivity, W/(m·K) | Room Temperature | ≥7 |

| 300℃ | ≥10 | |

| 600℃ | ≥12 | |

| 800℃ | ≥12 | |

| Alkali Resistance | U or LC | |

| Air permeability mDa | ≤10 | |

| Molten Iron Dissolution Index % | ≤28 | |

| Oxidation Rate % | ≤10 | |

Rongsheng Microporous Carbon Bricks Manufacturer

Rongsheng is a powerful manufacturer and seller of refractory bricks. Rongsheng can provide the design, supply, and construction of lining materials for high-temperature industrial furnaces. Rongsheng’s blast furnace microporous carbon bricks are of high quality and long service life. If you have a project that requires the purchase of high-quality blast furnace carbon bricks, electric furnace carbon blocks, and aluminum electrolytic cell carbon blocks, please choose Rongsheng. Contact Rongsheng for free samples and quotes.