Silica Bricks for Hot Blast Furnaces

- Small creep rate.

- High strength.

- Good thermal shock resistance.

We are Here to Help!

Email: sales@hy-refractory.com

WhatsApp: +86 185 3831 2977

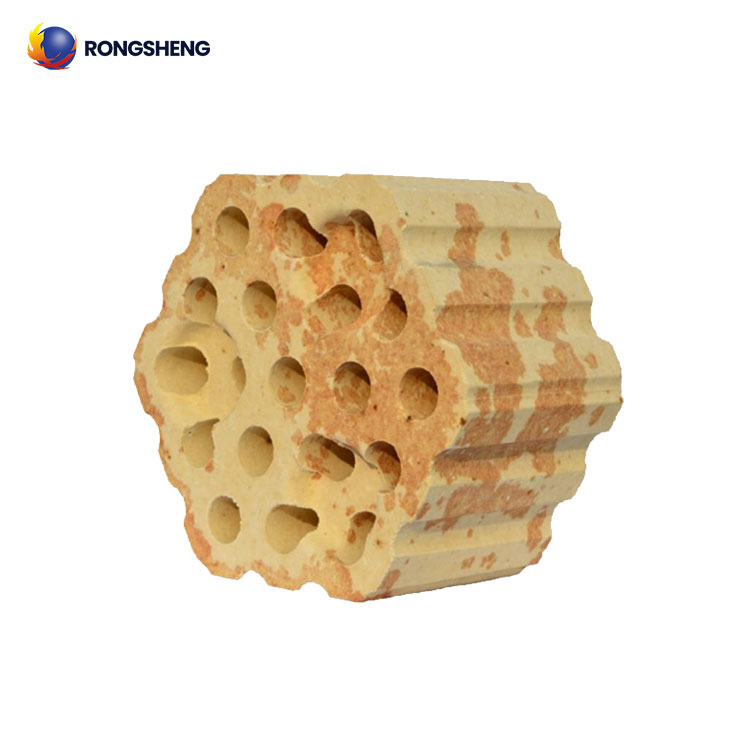

Rongsheng Silica Bricks for Hot Blast Furnaces for Sale. With the increase of hot blast furnace air temperature, the use conditions of hot blast furnace refractory materials are becoming more and more demanding. When the air temperature is higher than 1200℃, traditional high-aluminum products can no longer meet the use requirements of its high-temperature parts. At high temperatures, silica bricks have the advantages of a small creep rate, high strength, and good thermal shock resistance. Therefore, silica bricks are widely used in the top, partition walls, and upper part of the regenerator of large hot blast furnaces. Rongsheng Manufacturer can provide high-quality silica bricks for hot-blast furnaces and silica checker bricks for hot-blast furnaces. Contact Rongsheng for free samples and quotes.

Physical and Chemical Indicators of Silica Bricks for Hot Blast Furnaces

Silica bricks RG-95 for hot blast furnaces adopt the product standard YB/T133-1998. Physical and chemical indicators of silica bricks RG-95 for hot blast furnaces.

| Physical and Chemical Indicators of Silica Bricks RG-95 for Hot Blast Furnaces | ||

| Items | Vault and Furnace Wall Silica Bricks | Silica Checker Bricks |

| SiO2 % | ≥95 | |

| Creep Rate (0.2MPa, 1550℃×50h) % | 0.8 | |

| Apparent Porosity % | ≤22 | ≤23 |

| Compressive Strength at Room Temperature MPa | ≥35 | ≥30 |

| True Density g/cm3 | ≤2.35 | |

| Linear Expansion Rate (1000℃) % | ≤1.26 | |

Physical and Chemical Indicators of Silica Bricks for Hot Blast Furnaces in Rongsheng

| Physical and Chemical Indicators of Silica Bricks for Hot Blast Furnaces | ||

| Items | Standard Value | Typical Value |

| SiO2 | ≥95.5 | 96 |

| Apparent Porosity % | ≤21 | 19 |

| True Density g/cm3 | ≤2.34 | 2.32 |

| Compressive Strength at Room Temperature MPa | ≥35 | 52 |

| Linear Expansion Rate (1000℃) % | ≤1.25 | 1.20 |

| Creep Rate (0.2MPa, 1500℃×50h) % | ≤0.3 | 0.25 |

| Re-burning Linear Expansion Rate (1450℃×2h) % | 0 ~ 0.2 | 0 |

| 0.2MPa Load Softening Start Temperature ℃ | ≥1660 | 1670 |

| Residual Quartz % | ≤1.0 | ≤0.5 |